-

Industrial Bearings

- Deep Groove Ball Bearings

- Self-Aligning Ball Bearings

- Angular Contact Ball Bearings

- Cylindrical Roller Bearings

- Taper Roller Bearings

- Spherical Roller Bearings

- Bearing housing or Accessories

- Miniature Bearing

- Thrust ball bearing

- Radial Spherical Plain Bearing

- Pillow Block Bearing

- Needle Roller Bearings

- Automotive Bearings

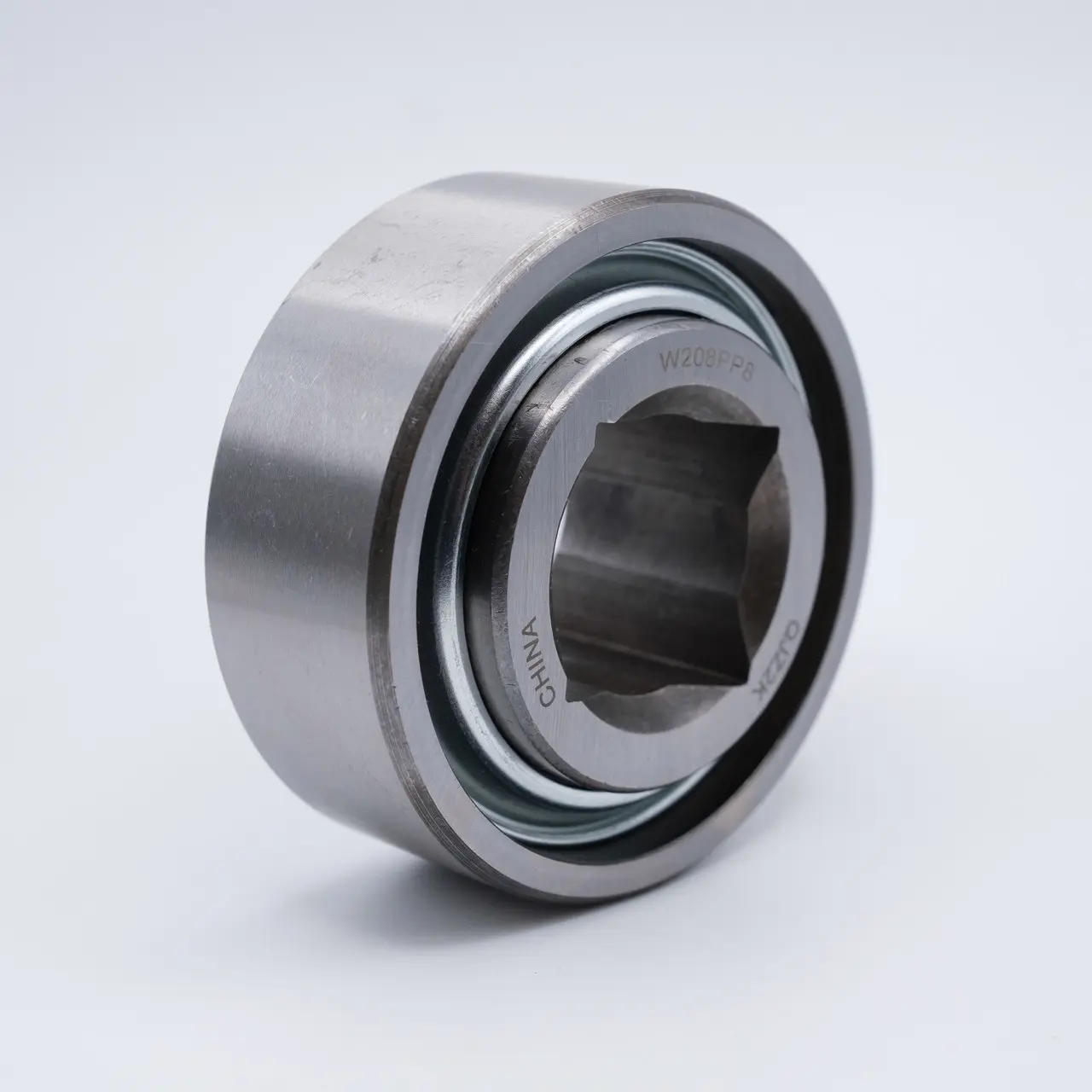

- Agricultural Bearings

- Special Material Bearings

W211PP3 Heavy-Duty Agricultural Bearing

W211PP3 Heavy-Duty Agricultural Bearing | Sealed Solution for Combines & Tractors

At GNB Bearing, we understand agricultural machinery faces dust, mud, and high-impact loads. Our newly released W211PP3 agricultural bearing solves these challenges with:

✅ PP3 Sealing System: Triple-lip rubber seals block contaminants

✅ Shock-Resistant Design: Optimized radial clearance for uneven terrain

✅ Corrosion Defense: Zinc-nickel plating (optional) for damp environments

Technical Specifications

| Parameter | Metric | Imperial |

|---|---|---|

| Bore Diameter (d) | 55 mm | 2.165" |

| Outer Diameter (D) | 100 mm | 3.937" |

| Width (B) | 21 mm | 0.827" |

| Dynamic Load | 15.2 kN | 3,417 lbf |

| Static Load | 9.8 kN | 2,203 lbf |

| Max Speed | 6,000 rpm | - |

| Seal Type | Dual PP3 Contact | (NBR Rubber) |

| Operating Temp | -40°C ~ +150°C | -40°F ~ 302°F |

| Accuracy | ABEC-1 | ISO P6 |

*Custom Options: C4 clearance, food-grade grease, stainless steel

Critical Applications

Solve failure points in:

-

🌾 Combine Harvesters: Grain auger bearings (John Deere S700 series)

-

🚜 Tractors: PTO shaft supports (Case IH Magnum)

-

🌽 Planters: Row unit parallel linkages (Kinze 3600)

-

💧 Irrigation Systems: Drive wheel hubs (Valley pivots)

Case Study: Replaced standard 6211 bearings in Claas Lexion combines, reducing downtime by 63% during 2023 US wheat harvest.

Why Farmers Choose W211PP3

| Problem | W211PP3 Solution |

|---|---|

| Dust/silt ingress | PP3 seals block 99% particulates |

| Lubrication washout | High-viscosity grease retention |

| Impact failures | Reinforced cage design |

| Corrosion pitting | Optional Zn-Ni coating |

GNB Bearing Advantage

Vertical Integration Benefits:

-

48-Hour Sample Service: Test bearings on your equipment

-

OEM Replacement Kits: Pre-packed with spacers/seals

-

Batch Traceability: Laser-marked + ISO 9001 certification